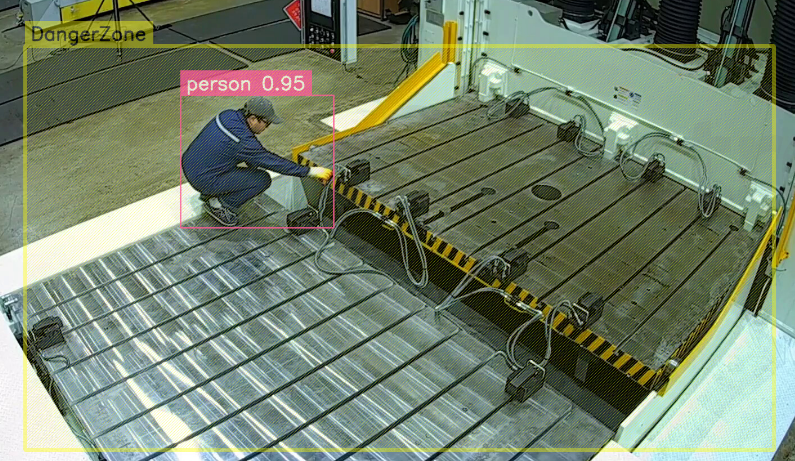

Worker Accident Risk Monitoring

Hazardous Accident Detection

When a worker excessively approaches a hazardous equipment area or a posture indicating a pinch risk is detected,

it immediately senses the danger signal, analyzes the situation, and reports the potential accident.

Worker Fall Detection

Continuously monitors changes in the worker's posture,

and issues immediate warnings upon falling, fainting, or acute abnormal behavior to support rapid intervention.

Dangerous Behavior Detection During Work

Real-time identification of safety rule violations such as cell phone use,

straying from safety zones, or approaching equipment,

proactively prevents dangerous behaviors that could lead to accidents.

The Process of Turning a Regular Camera into an AI Camera in Just 5 Minutes!

Detection Scenario Configuration

Easily write detection conditions using prompts.

Example: "Notify me if a worker has fallen down

or an accident occurs"

Zone Configuration

Set the zone for the hazardous area.

Detection will be performed within this specific zone.

Result Check & Optimization

Check the detection results and

modify the zone and scenario if necessary.

Early Identification of Danger Signs

Most accidents in manufacturing sites start with minor carelessness.

EVA continuously recognizes worker movements and equipment proximity,

proactively detects accident risks, and enables immediate response.

Real-time Control based on Physical AI

EVA goes beyond simple monitoring and can be linked to equipment control systems.

It executes automated actions such as immediate equipment shutdown and warning alerts when danger occurs,

realizing a Physical AI environment that prevents accidents before they happen.