Ensuring Safety Compliance Levels

Detection of Protective Equipment for Hazardous Material Work

Automatic recognition of mask usage during soldering and hazardous material handling,

proactively eliminating health risks and ensuring compliance with industrial safety guidelines.

The Process of Turning a Regular Camera into an AI Camera in Just 3 Minutes!

Detection Scenario Configuration

Easily write detection conditions using prompts.

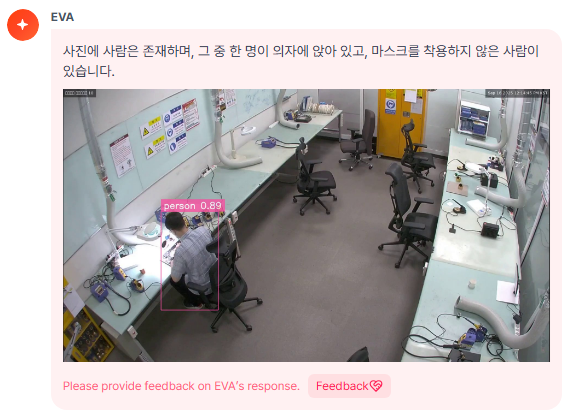

Example: "Person soldering while sitting on a chair is not wearing a mask"

Result Check & Optimization

Check the detection results and

modify the target and scenario if necessary.

Early Identification of Safety Non-Compliance

Accidents and industrial disasters in manufacturing sites often stem from violations of safety rules.

EVA continuously monitors the worker's protective gear usage and compliance with safety regulations,

allowing for early identification of risk factors and drastically reducing the possibility of accidents.

Automation of Compliance and Real-time Control

EVA goes beyond simply checking compliance status,

it integrates with access control and equipment control systems to execute immediate action upon non-compliance.

This realizes a Safety Automation (Physical AI) environment that guarantees worker safety.