Work Procedure Compliance

Overloading Detection

EVA detects overloaded conditions that exceed defined safety thresholds in logistics and work environments in real time,

identifying potential risks such as tipping accidents and equipment damage in advance.

By immediately recognizing violations of work procedures, EVA significantly reduces the likelihood of accidents.

Safety Vest Non-Compliance Detection

EVA automatically identifies whether workers are wearing safety vests within designated work areas

and detects missing protective equipment in real time.

This helps enforce safety regulations and minimizes the risk of industrial accidents.

Turn Any Standard Camera into an AI Camera in Just 3 Minutes — Here’s How

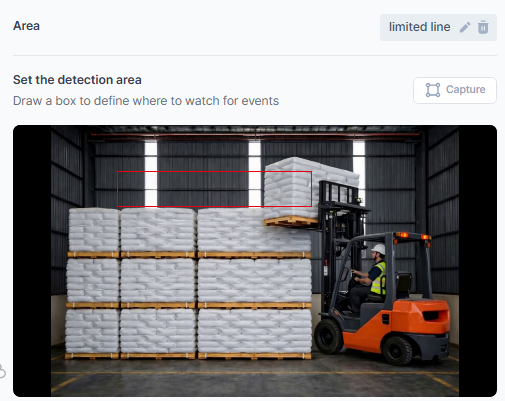

Define the Area

Define detection areas according to your work procedures.

AI detection will be applied only within the specified zones.

Configure Detection Scenarios

Easily define detection conditions using natural language prompts.

"Notify me if any cargo is placed inside the restricted area."

Review & Optimize Results

Review detection results in real time

and refine targets or scenarios as needed.

Early Detection of Work Procedure Violations

Non-compliance with work procedures is one of the leading causes of major industrial accidents.

EVA continuously analyzes on-site working conditions to identify violations early and proactively prevent potential incidents before they escalate.

Automated Safety Management & Environment Control

EVA goes beyond simple detection by integrating with alerting, logging, and monitoring systems to systematically manage work procedure compliance.

This enables automated safety management while simultaneously improving operational efficiency.