Manufacturing

Bolt Fastening Inspection

Improve both production efficiency and quality with real-time defect detection.Challenges

Having trouble responding quickly to new defect types?

Problem

- Inspection errors in processes performed by workers, such as bolt fastening, lead to quality issues.

- Existing rule-based inspection systems can only detect limited defect types.

Solution

The AI model continuously learns the field situation to respond instantly to new defects.

Solution

Continuous quality improvement with AI optimized for industrial sites

- Immediate and Accurate Anomaly Detection

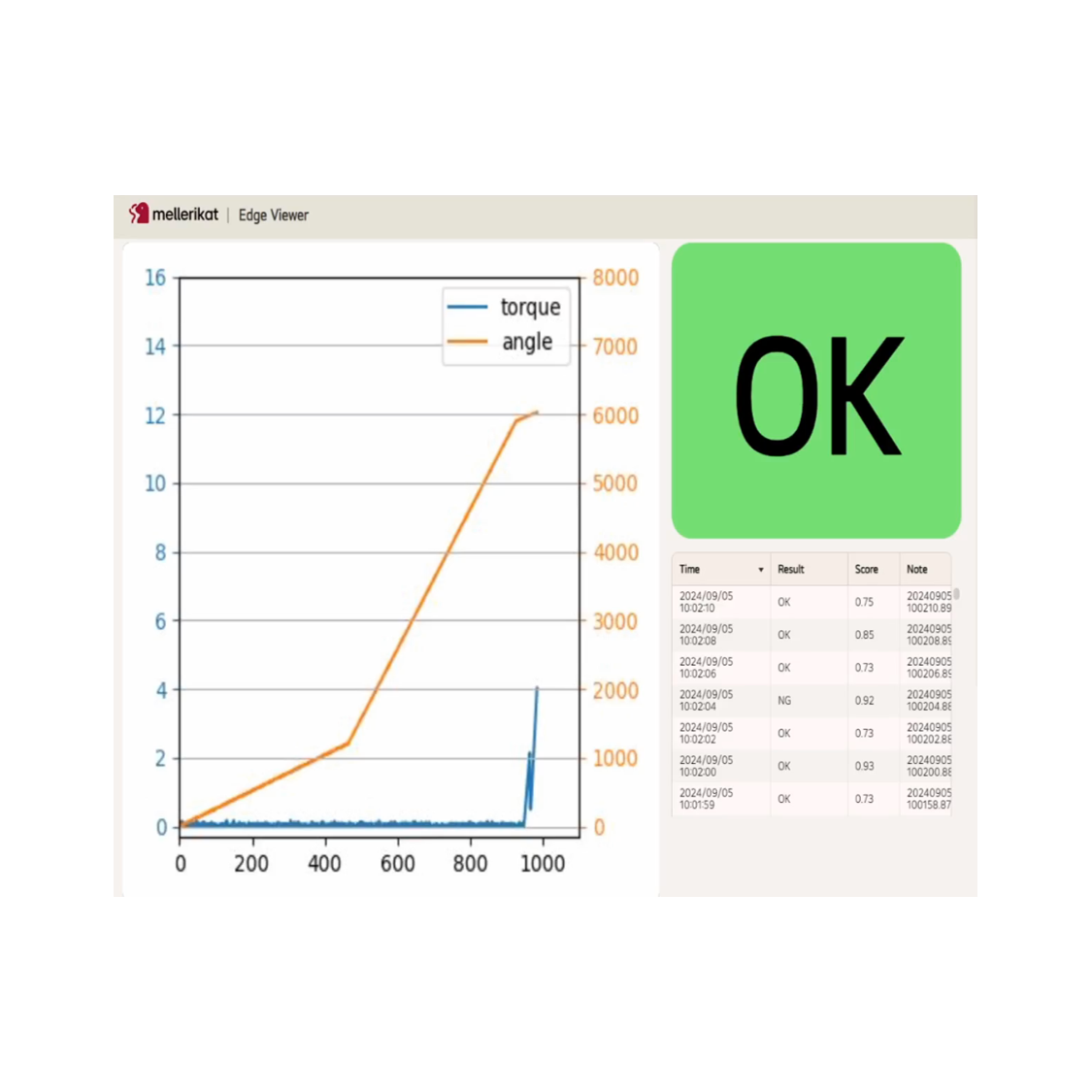

- Analyzes time-series data generated during bolt fastening to determine anomalies instantly.This solution is developed to solve issues occurring in mass production factories with repetitive tasks. While the boundary between normal and abnormal data is clear, data with similar patterns, such as bolt mixing or misaligned fastening, are difficult to judge with existing systems. To overcome this, advanced feature extraction techniques are used to accurately discern complex factors.

This AI-based solution provides immediate judgment results without affecting the production cycle. Specifically, the Edge App makes optimal use of device resources to complete judgments within one second, enabling quick and accurate real-time judgment.

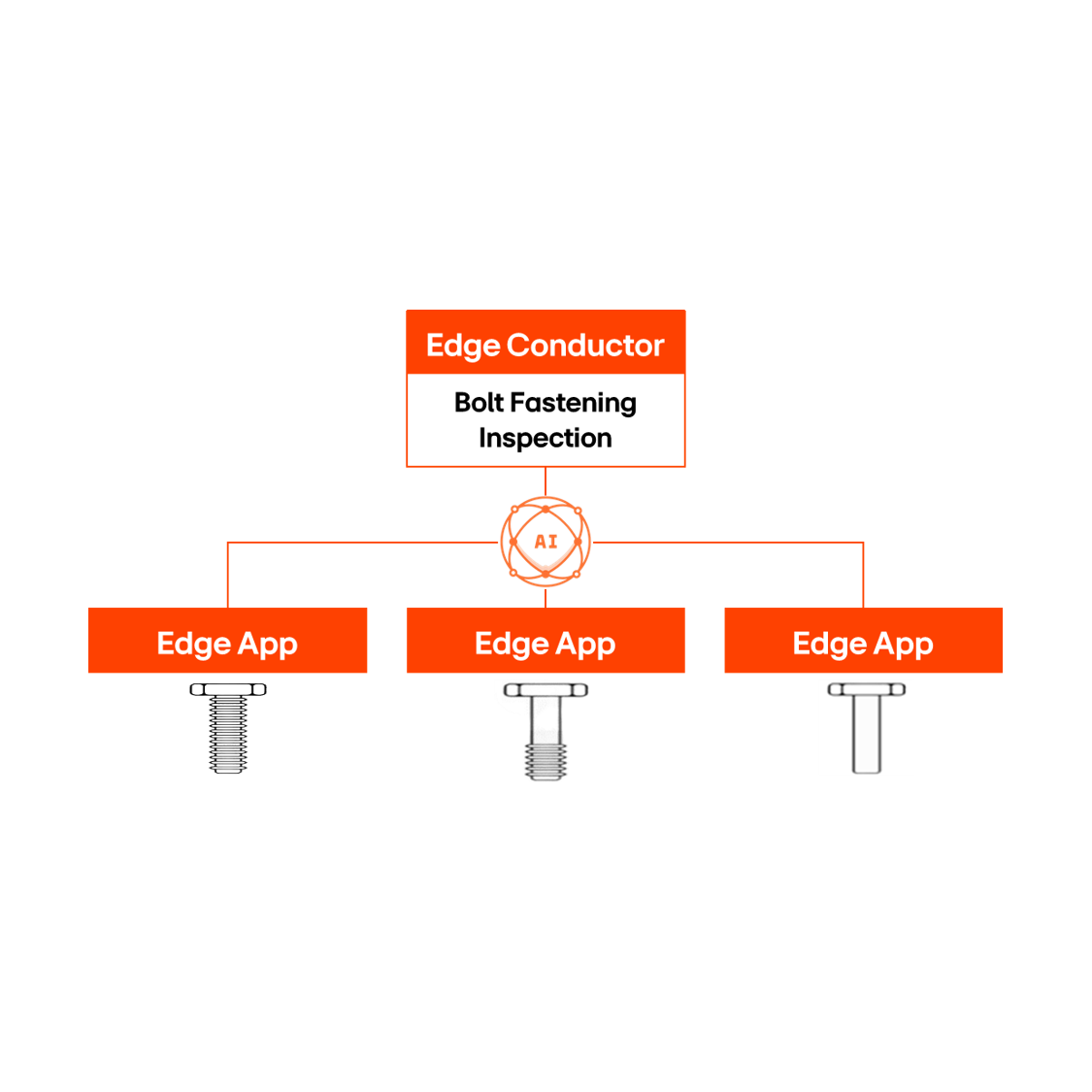

- Scalability

- Easily manage and efficiently operate AI models despite various processes and bolt specifications.Through an AI solution with already established modeling structures for bolt fastening, you can easily create datasets and train and deploy models using Edge Conductor with data collected from various patterns at each Edge. This solution enables efficient operation even in complex processes, making it easy for users to operate even with numerous applicable points.

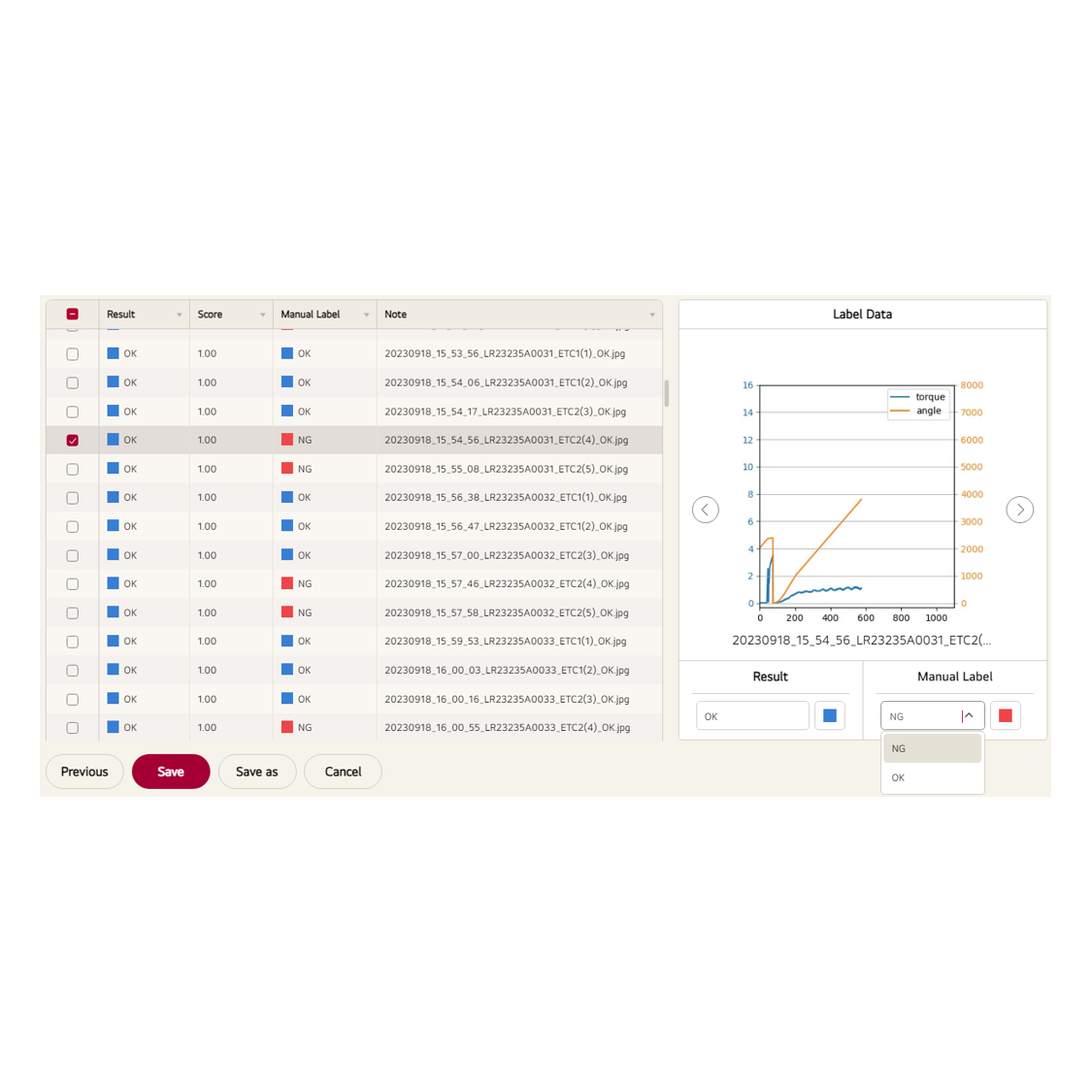

- Continuous Model Updates and Operation

- Field managers label data as normal and abnormal to respond swiftly to changes.While rule-based systems struggle to respond to changes, the Mellerikat platform addresses these issues. Automated retraining and deployment processes enable customers to easily update and operate AI models themselves. By centrally managing AI models from various sites with Edge Conductor, you can respond nimbly to changes and continuously improve performance.

Applicable Industries

Quality Innovation Realized in Various Industries

Apply an accurate anomaly detection solution to products and semi-products produced by workers or automated equipment in the manufacturing field. Time-series data analysis contributes to quality control, lowering defect rates, and increasing work efficiency. Process Improvement for Workers

Process Improvement for WorkersAnalyzes time-series process data performed repetitively by workers to reduce skill gaps and prevent quality issues in advance.

Production Process Quality Management

Production Process Quality ManagementAnalyzes various time-series data generated during manufacturing processes to maintain process quality and minimize the occurrence of defective products.

Predictive Maintenance

Predictive MaintenanceMonitors time-series data from automated equipment to detect early signs of anomalies and minimize downtime with preventive maintenance.

" This solution contributes to quality management and work efficiency improvement in various processes,

enhancing the level of data analysis and anomaly detection in production processes. "