Manufacturing

Vision Inspection

Improve quality and efficiency with AI vision inspection optimized for industrial sites.Challenges

Struggling with a difficult-to-manage vision inspection system?

Problem

- Securing high-quality training data is challenging, impacting AI vision inspection performance.

- Real-time processing requires high-performance system optimization.

- Continuous performance maintenance needs expert personnel.

Solution

Achieve intelligent inspection with efficient vision data management and integrated model operation on the field.

Solution

Continuous quality enhancement with vision inspection optimized for Manufacturing

- AI Solution Customized for Manufacturing Processes

- Provides flexible AI vision solutions tailored to the field situation and data.If collecting defect images is difficult, the Anomaly Detection solution uses normal images to diagnose anomalies. If sufficient defect images are available, the Vision Classification solution rigorously identifies defects. Users can adjust detection rates and use the latest models to detect fine defects in high-resolution images. Explainable AI (XAI) aids in understanding results and visualizing issue locations for rework or error processing.

- Immediate Judgment Results

- Provides immediate judgment results without affecting the production cycle with real-time processing.The Edge App ensures judgments without delay by making optimal use of resources in field systems and organically applies to production systems. This improves production efficiency and minimizes the occurrence of defective products.

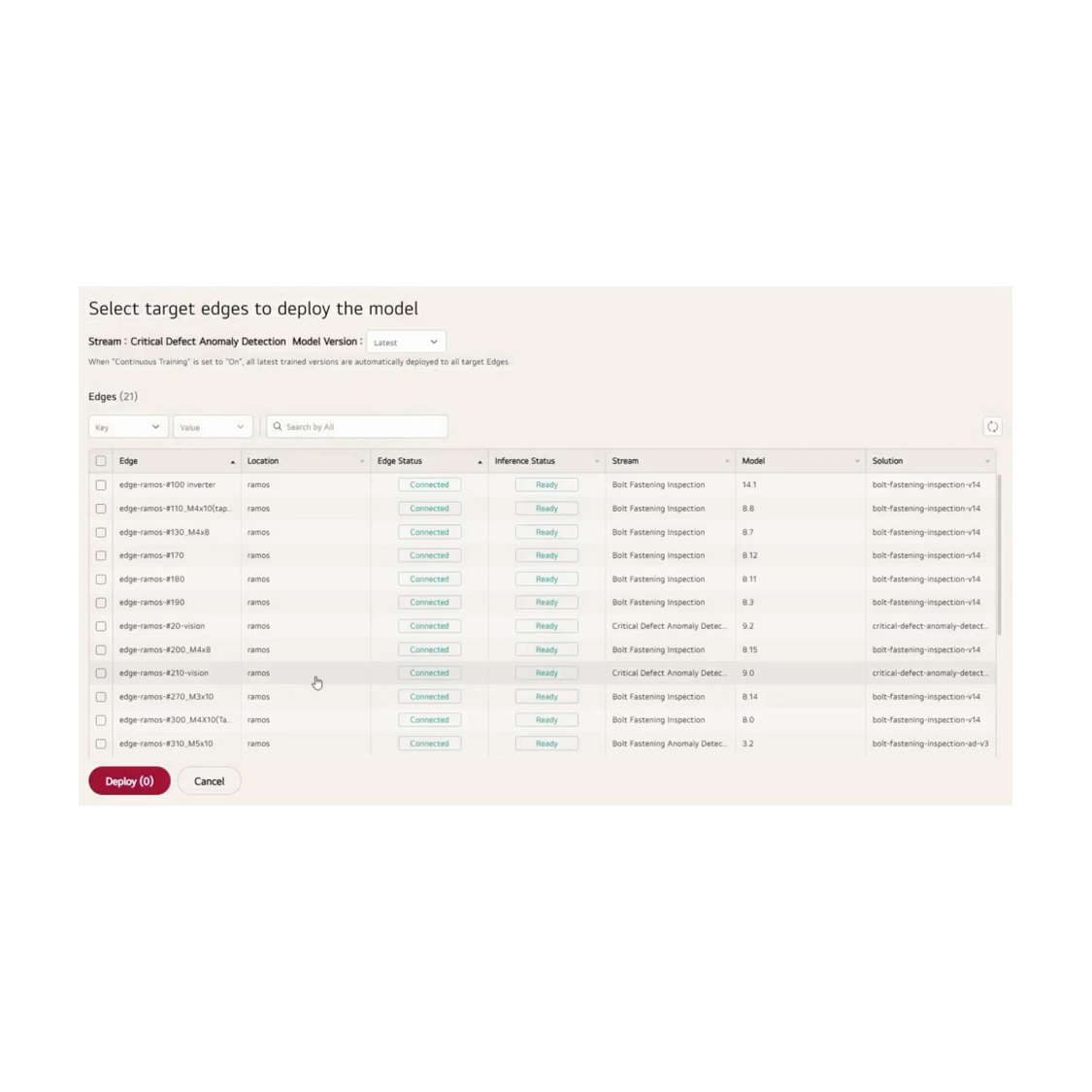

- Continuous Model Updates and Operation

- Continuously updates the model to respond quickly to changing field conditions.Prevents degradation of AI model performance due to new fault types, component color changes, and hardware equipment movements. Automated re-training and deployment with Edge Conductor make it easy to update and operate AI models, and centralized management of AI models from multiple sites allows for nimble responses to changes and continuous performance improvements. Continuous data acquisition ensures steady performance improvement of the system, and it can be efficiently operated even in various processes and situations. Users can easily operate the system even with many application points.

Applicable Industries

Quality Innovation and Expected Effects Realized in Various Industries

AI-based vision inspection systems are applicable to various industries, including manufacturing sites, enhancing task inspection and quality management. This reduces defect rates and increases work efficiency, improving overall productivity and quality. Product Vision Inspection

Product Vision InspectionDetects external defects in products to ensure quality and increase customer satisfaction.

Worker Process Compliance Inspection

Worker Process Compliance InspectionVerifies compliance with work process guidelines to maintain consistency and efficiency in tasks.

Livestock Growth Inspection

Livestock Growth InspectionMonitors growth conditions in the livestock industry to optimize health and productivity.

" This solution contributes to quality management and work efficiency improvement in various processes,

enhancing the level of vision inspection in production processes. "