EDIS

EDIS (Edge Diagnostics and Inspection System) is an Edge AI solution that enables real-time analysis and diagnostics of diverse facility data in industrial manufacturing sites.

By leveraging AI to analyze sensor, signal, and image data—including both numerical and vision data—EDIS automates diagnostics, inspection, and predictive maintenance, driving innovation in productivity, quality, and safety.

Listen to the podcast below for more details about EDIS.

Effortless AI Transformation for Manufacturing Facilities

Instant AI Diagnostics with Just Edge App Installation

Edge App collects facility data in real-time and utilizes AI to instantly detect a variety of patterns, such as anomalies, quality issues, and equipment aging.

You can either convert existing production equipment directly into AI-enabled devices, or simply connect a dedicated edge computing device and install Edge App to introduce AI without additional processes.

Edge App supports all manufacturing processes—including assembly, machining, welding, and pressing—enabling seamless integration with production lines through real-time monitoring, automated decisions, and rapid feedback.

Flexible Integration with Existing Systems

After installing Edge App, simply designate the folder to monitor for inference data generation. Whenever a new file is created, inference is immediately performed and results are delivered to Edge Viewer.

Edge Viewer offers flexible window sizing for viewing inference results, and provides detailed insights when image or XAI data is available.

AI inference results can be provided wherever needed on-site, ensuring seamless workflow integration, and can even be transmitted to PLCs for direct feedback into production processes.

Video: Context-aware agent prompt for field operations

AI Models Specialized for Manufacturing

Tailored Diagnostics for Your Facility

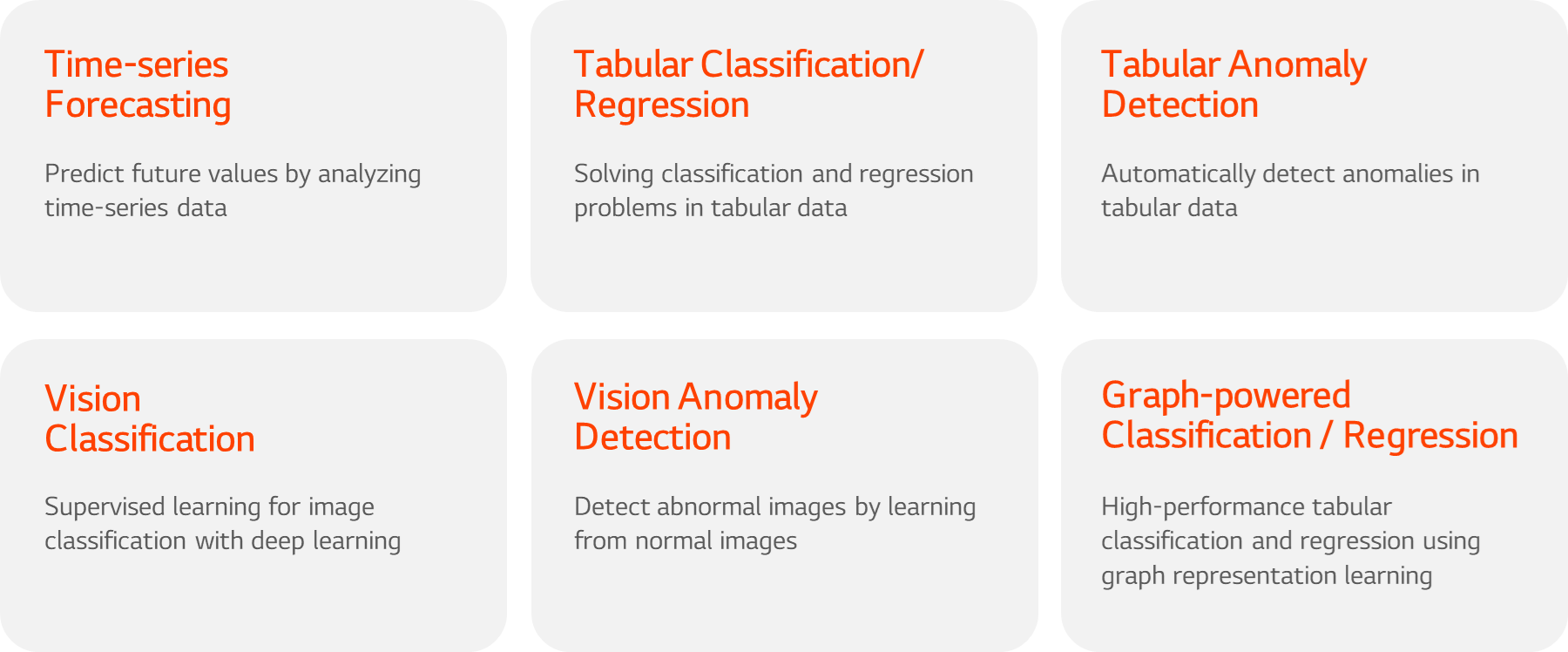

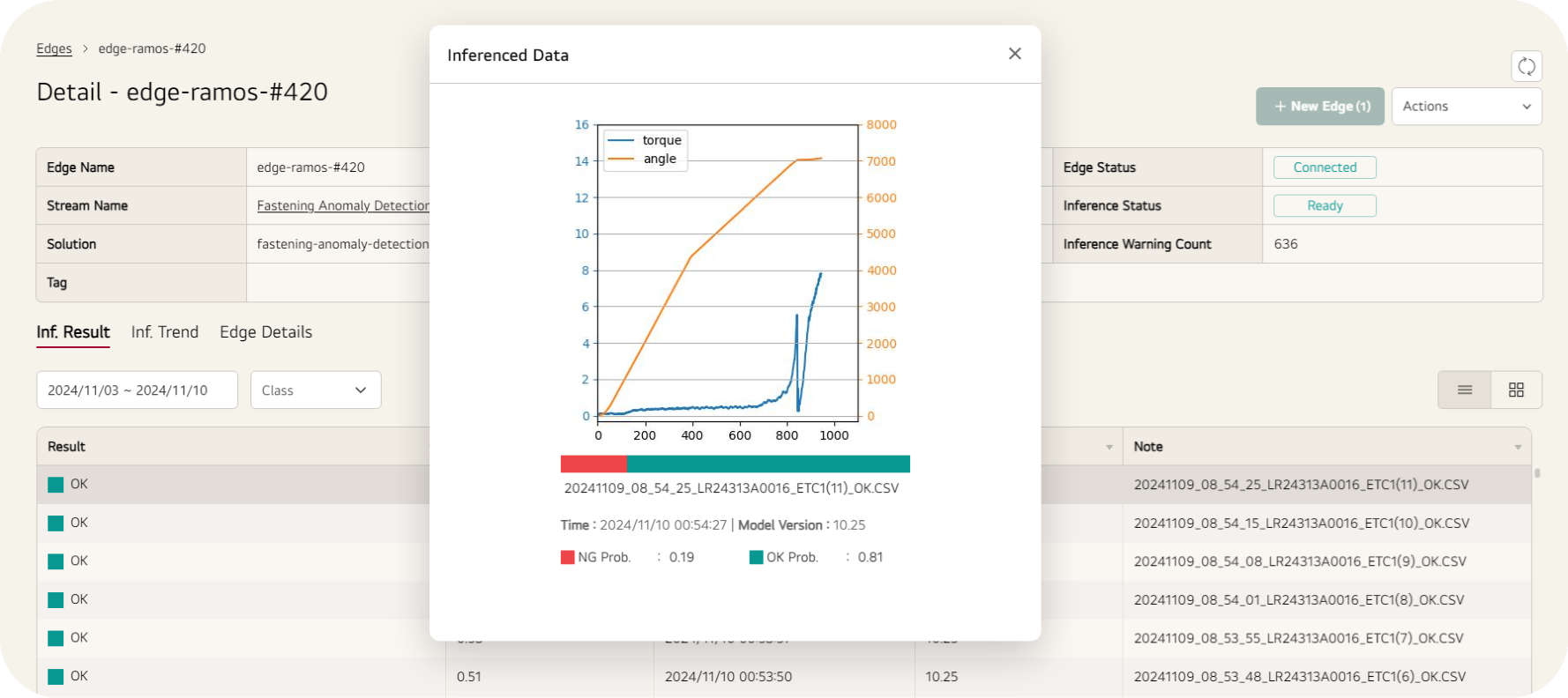

EDIS offers a wide range of AI Contents—such as Tabular Classification, Regression, Forecasting, and Anomaly Detection—that can be rapidly deployed in manufacturing environments.

Suitable AI Contents are selected based on your needs and available data, with model parameters and training processes customized for your field data.

If you have plentiful data with clear labels, Classification Contents is recommended. For cases where abnormal data is hard to collect, Anomaly Detection can be selected.

Parameters and thresholds are easily optimized to fit the unique characteristics of your site data.

Vision AI Inspection

AI-Based Quality Inspection

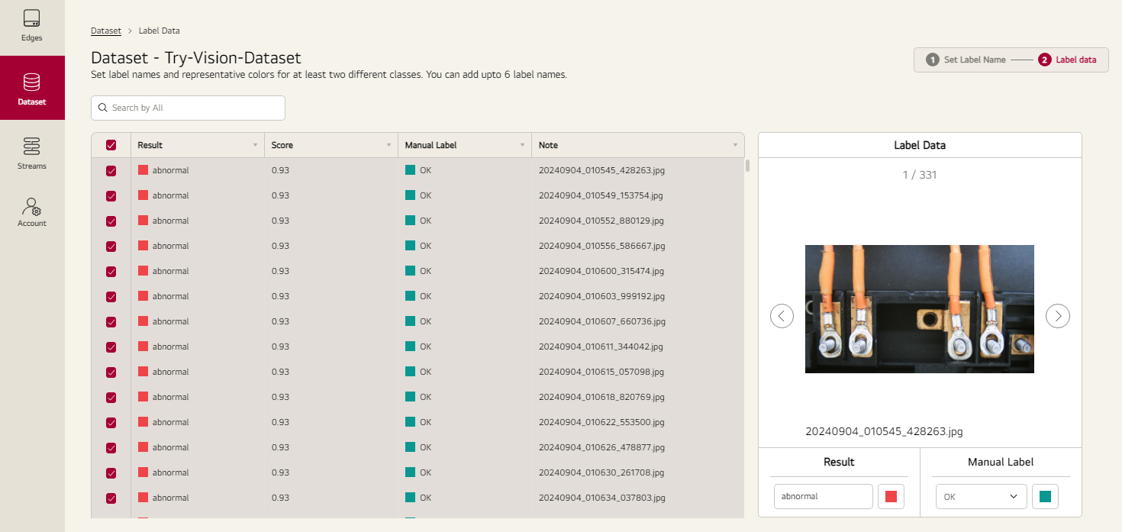

Harness images generated on manufacturing sites to provide precise, AI-powered quality inspections.

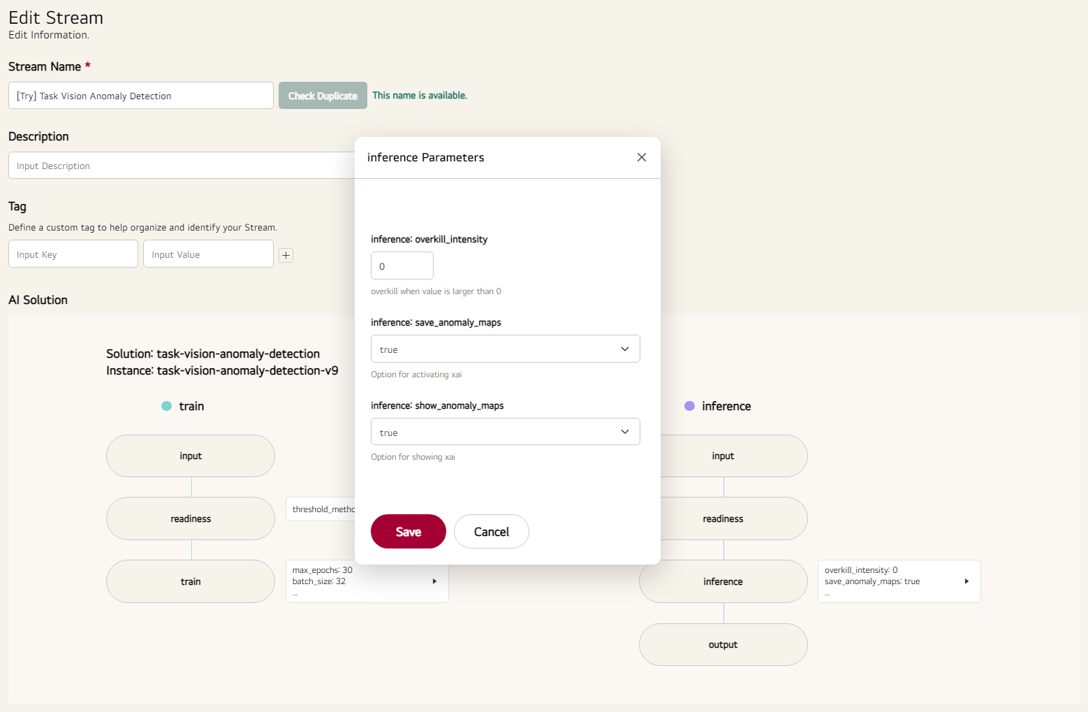

Detect anomalies using only normal images via Anomaly Detection, or use Vision Classification when defect images are available—covering diverse defect detection scenarios.

Over-inspection and under-inspection rates can be adjusted to meet site needs, and Explainable AI (XAI) visualizes defect locations, empowering operators and managers to respond swiftly.

Multiple inspection points can be centrally managed using only image data.

Integrated Model Management & Operation

Efficient AI Operation for the Field

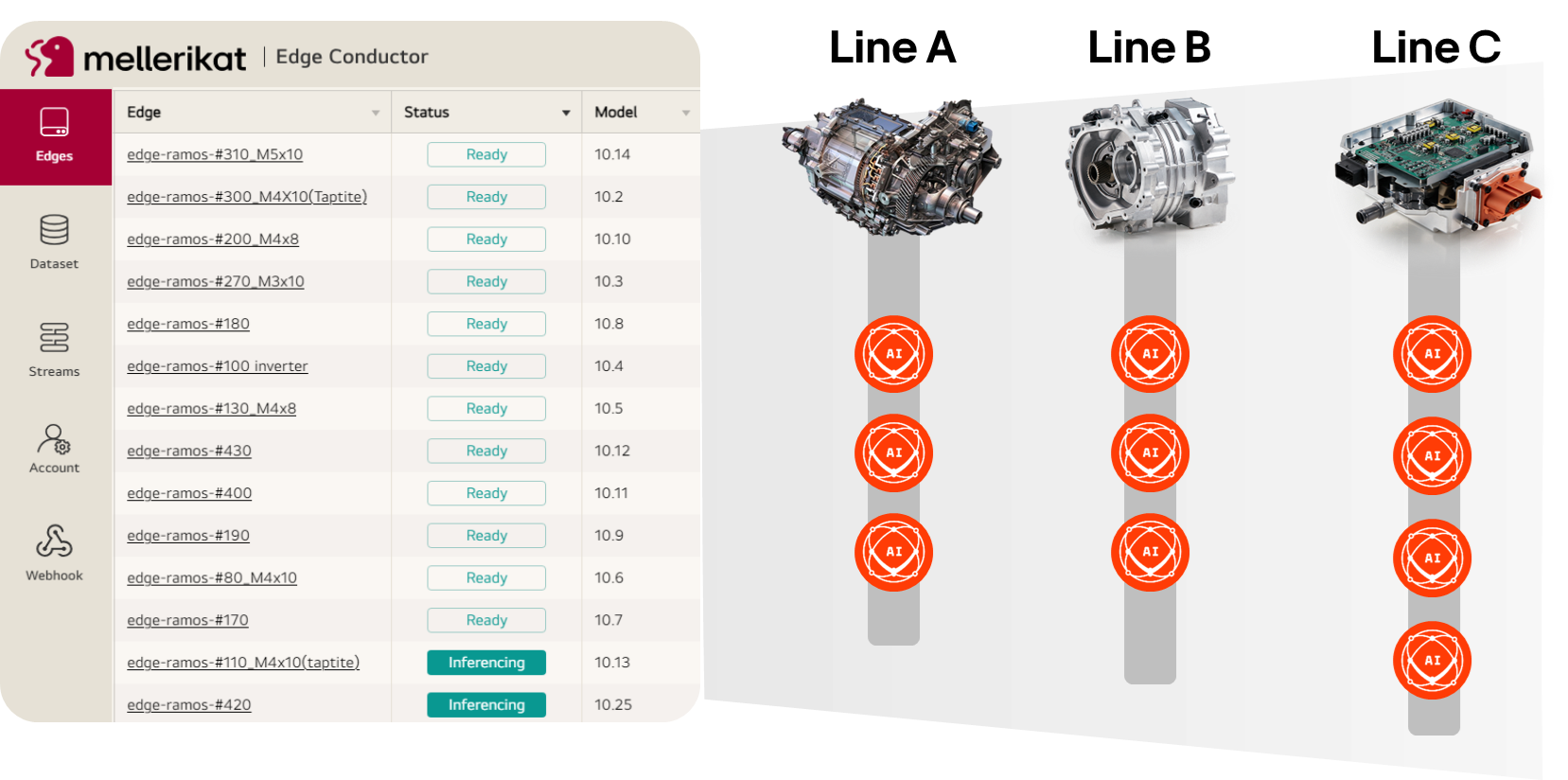

Edge App and Edge Conductor let you manage AI models across multiple sites, processes, and devices all at once.

There’s no longer any need for manual data copying or model handling.

Monitor the status of every model operating within each Edge App through Edge Conductor.

Check detailed inference results from all deployed models at a glance.

From Data Collection to Model Deployment—Easy for Everyone

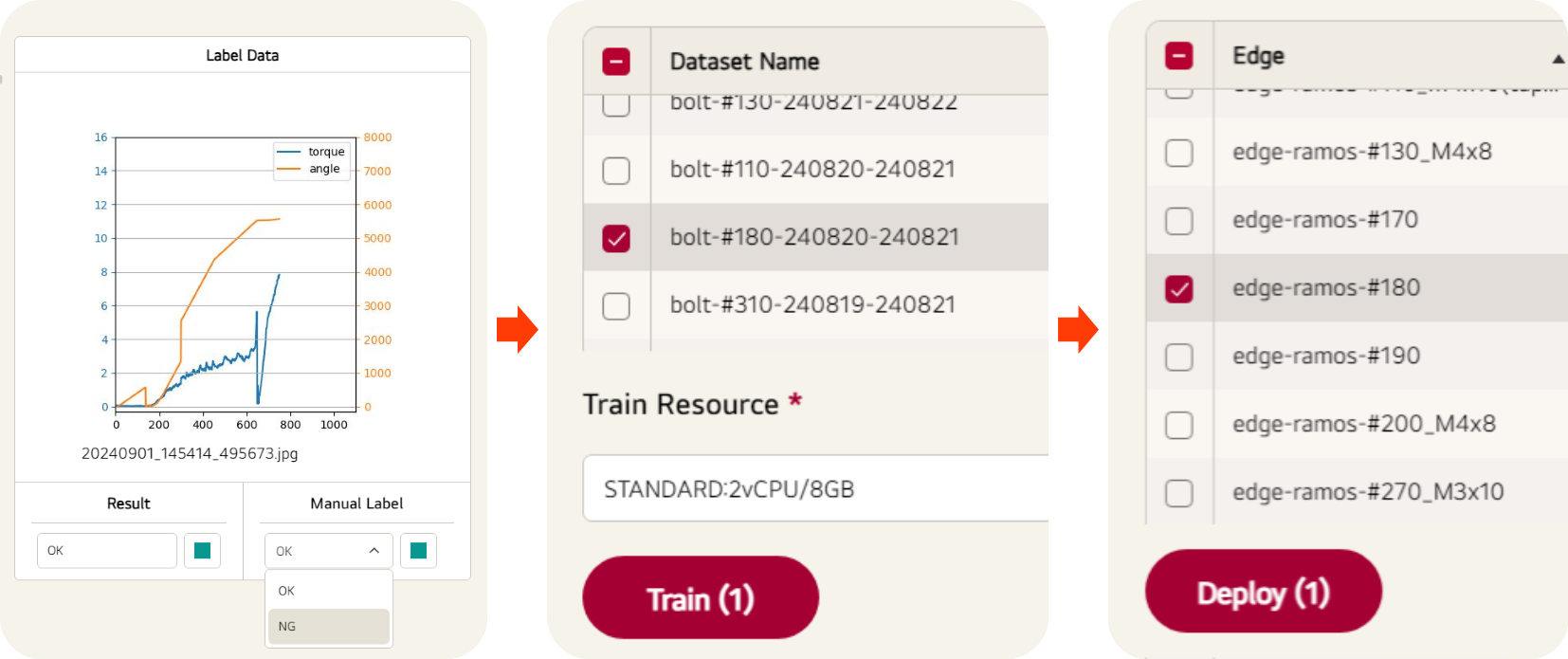

Site managers can directly collect data and label it as normal or abnormal, enabling AI model training and updates to keep pace with rapidly changing field conditions.

With automated retraining and deployment workflows, customers can efficiently update and operate their own AI models.

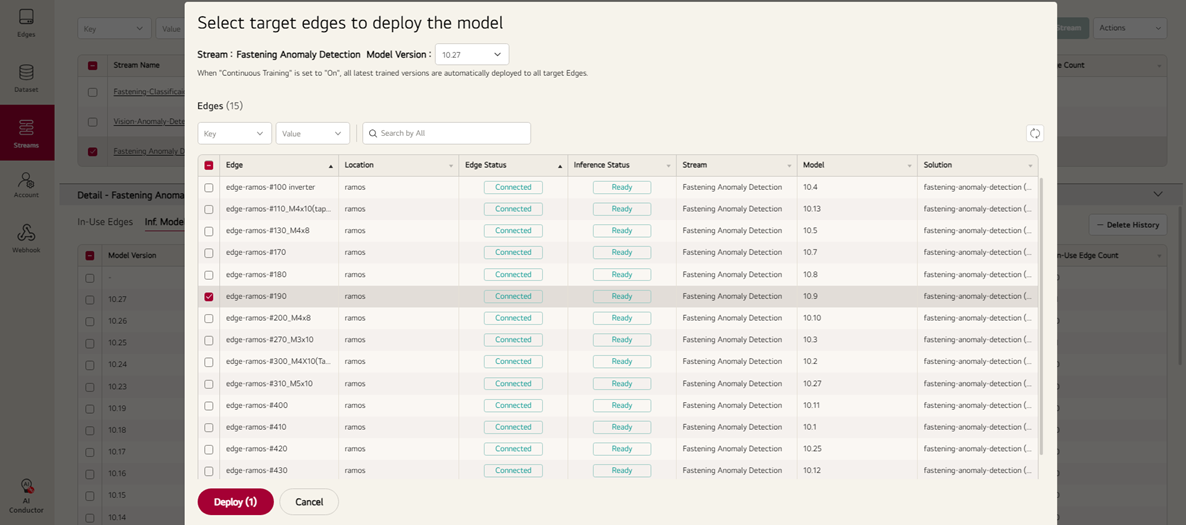

Edge Conductor provides unified management of models across all Edge devices, allowing for agile responses to changes and continuous improvement in performance.

Choose your dataset and training infrastructure, then request training and deployment with just a few clicks.

Field experts with domain knowledge can review and label images, focusing only on cases where the model is uncertain based on Confidence Score.

Select your target Edge devices and deploy models instantly.

Video: Deploying to dozens of Edge devices at once

Architecture & Security

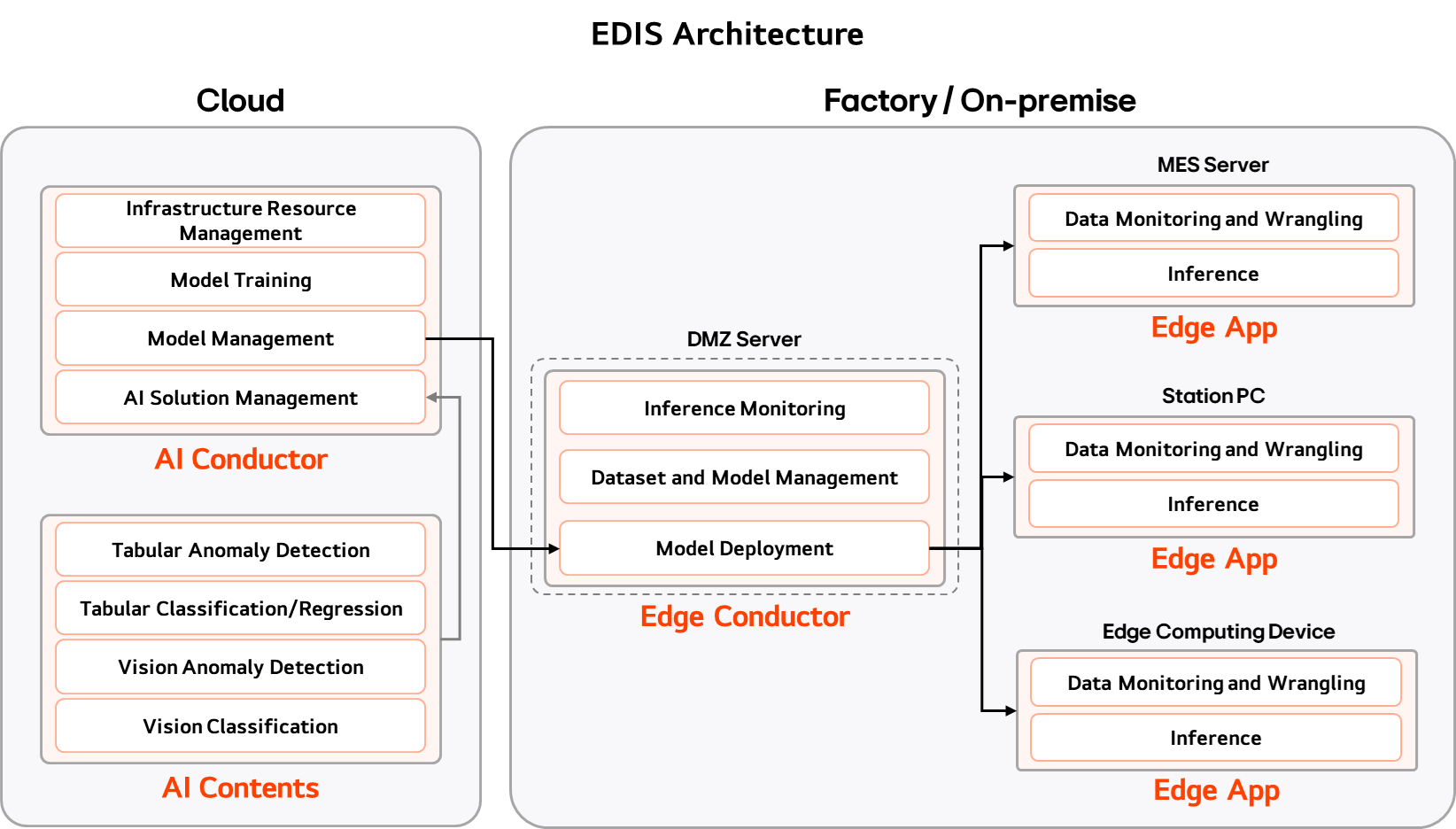

Cloud and On-premise Architecture Optimized for Manufacturing

Manufacturing environments operate securely on internal networks completely isolated from the outside world. This isolation creates challenges when deploying cloud-based AI models, and opening firewalls for dozens of processes increases security risks.

EDIS installs Edge Conductor on the manufacturing DMZ server to connect site Edge devices and provides a single channel to the cloud AI Conductor.

Only datasets selected for model training are transferred from Edge Conductor to the cloud. Once training is completed, Edge Conductor receives the model file from AI Conductor for deployment.

Data flow is strictly controlled in both inbound and outbound directions, sending only selected datasets to the cloud to minimize security risks.