Challenges

Predicting Optimal Inventory for Global Service Parts

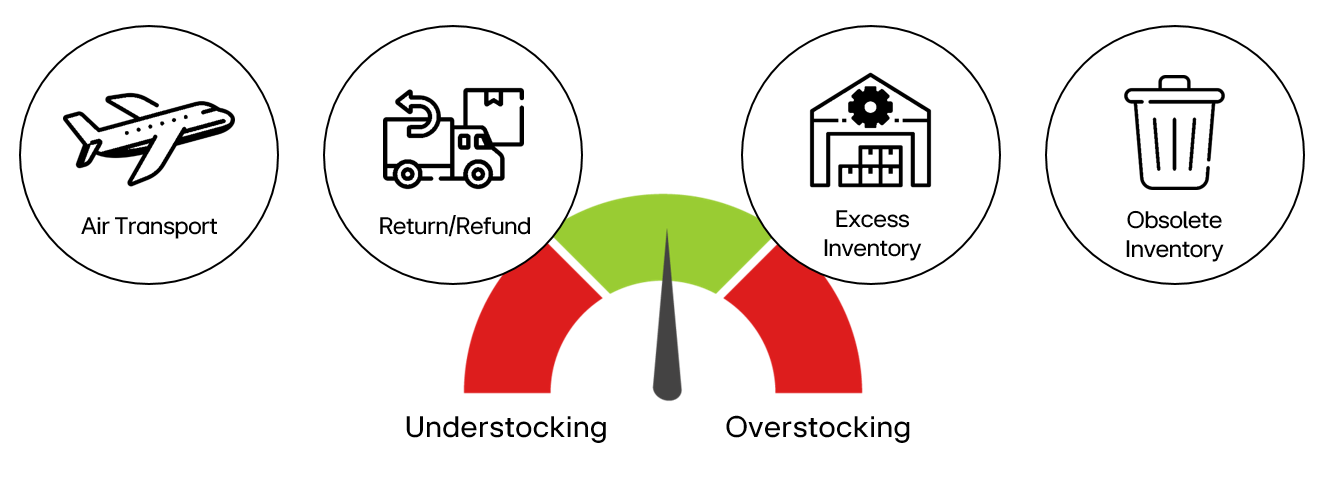

LG Electronics operates up to 800,000 service parts, and each major warehouse in global subsidiaries must maintain an appropriate inventory level to minimize costs from overstocking or shortages.

For many service parts, demand is very low or the range and pattern of demand vary greatly by country and region, making prediction difficult.

AI Solution Optimized for Service Part Demand Data

Strengths of Forecasting AI Contents

Mellerikat provides Forecasting AI Contents optimized for real problem-solving by combining

the knowledge of domain experts and data scientists from various industries.

With powerful preprocessing, data is expanded and refined to be suitable for time series models,

and various models such as Prophet, NBeat, TFT, and DLinear are supported,

allowing the optimal prediction model to be applied according to data characteristics and patterns.

The latest research-based models are continuously provided, making it easy to change models and compare or update prediction performance.

In addition, parameter tuning and weight settings allow for customized predictions tailored to regional cost structures or service policies.

Customized Prediction Based on Data Patterns

Forecasting AI Contents automatically analyzes demand patterns and time series characteristics of the data to generate the optimal prediction model for each SKU.

Over 90% of service part demand follows a lumpy pattern (irregular and infrequent), while only some SKUs show repetitive time series patterns.

For SKUs with high irregularity, the TFT model is applied, and for SKUs with clear patterns, the DLinear model is used to maximize prediction performance.

Fine-Tuning According to Regional Policies

Since logistics and inventory cost structures differ by subsidiary location and policy, regions with high warehouse maintenance costs may prefer under-forecasting, while regions where service delivery time is critical may prefer over-forecasting.

Forecasting AI Contents provides weight adjustment functions for over/under forecasting,

enabling the construction of prediction models optimized for costs and service policies by region.

Model Operation for Continuous Performance Optimization

Automation and Efficiency Based on the MLOps Framework

Service part demand forecasting must continuously reflect the latest data to quickly respond to changes in data distribution,

such as new product launches or economic changes.

Mellerikat's MLOps Solution automates the entire prediction process, including data preprocessing, model training, evaluation, and deployment, minimizing repetitive tasks and maximizing operational efficiency.

Operation of Customized Models by Part Importance and Region

Service parts are classified as core or general parts according to their utilization and cost,

and there are significant differences in demand patterns and time series characteristics by continent.

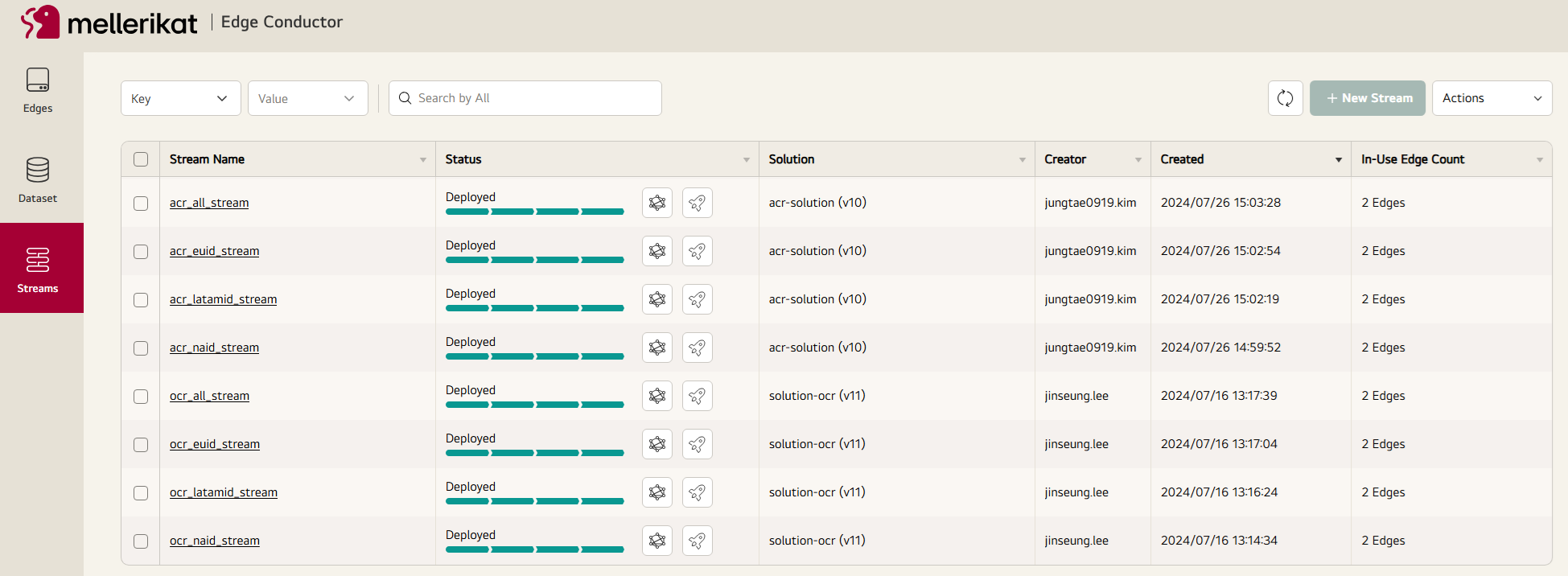

Edge Conductor operates models in pipelines separated by part importance,

and learns and deploys customized models by continent to maximize prediction performance.

Dozens of models are automatically trained and predicted, ensuring both operational efficiency and accuracy.

Integration with Splunk

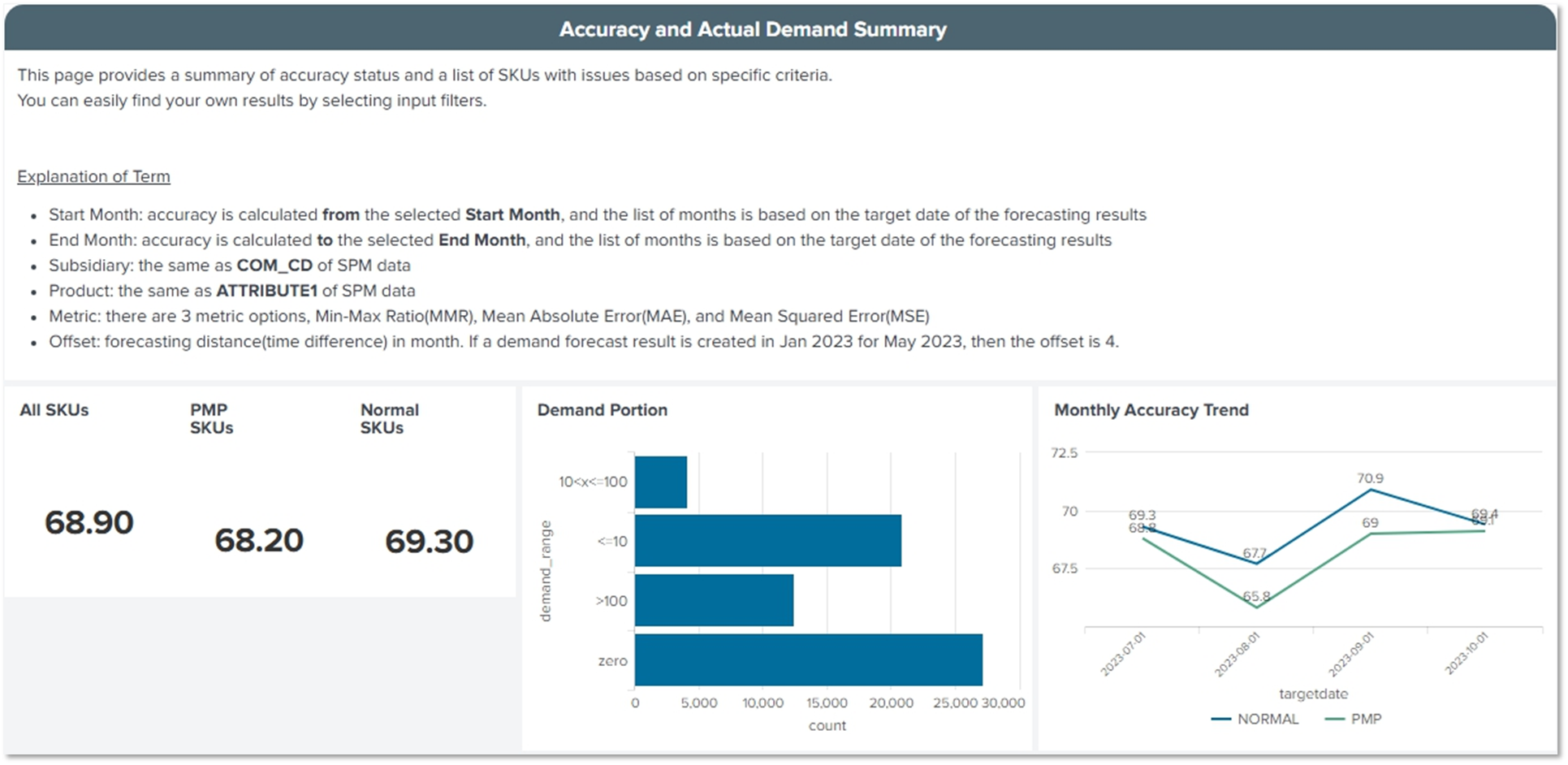

Large-Scale Prediction Monitoring Based on Splunk

Predictions for 800,000 parts involve processing massive amounts of data, including historical data.

By loading prediction data into Splunk and providing dashboards that cover both real-time and historical data,

prediction performance can be systematically monitored.