EVA: A New Standard for Safety Management Beyond Physical Sensors

EVA Accelerates the Golden Time for Fire Response

Securing the “golden time” during a fire incident in manufacturing facilities is one of the most critical factors in protecting both human life and physical assets. Traditional fire detection systems have long relied on physical sensors, but camera-based intelligent detection technologies are now rapidly replacing this role.

In this post, we analyze EVA’s smoke detection performance through a real-world validation test conducted at an LG Electronics facility and examine the technical significance of the results.

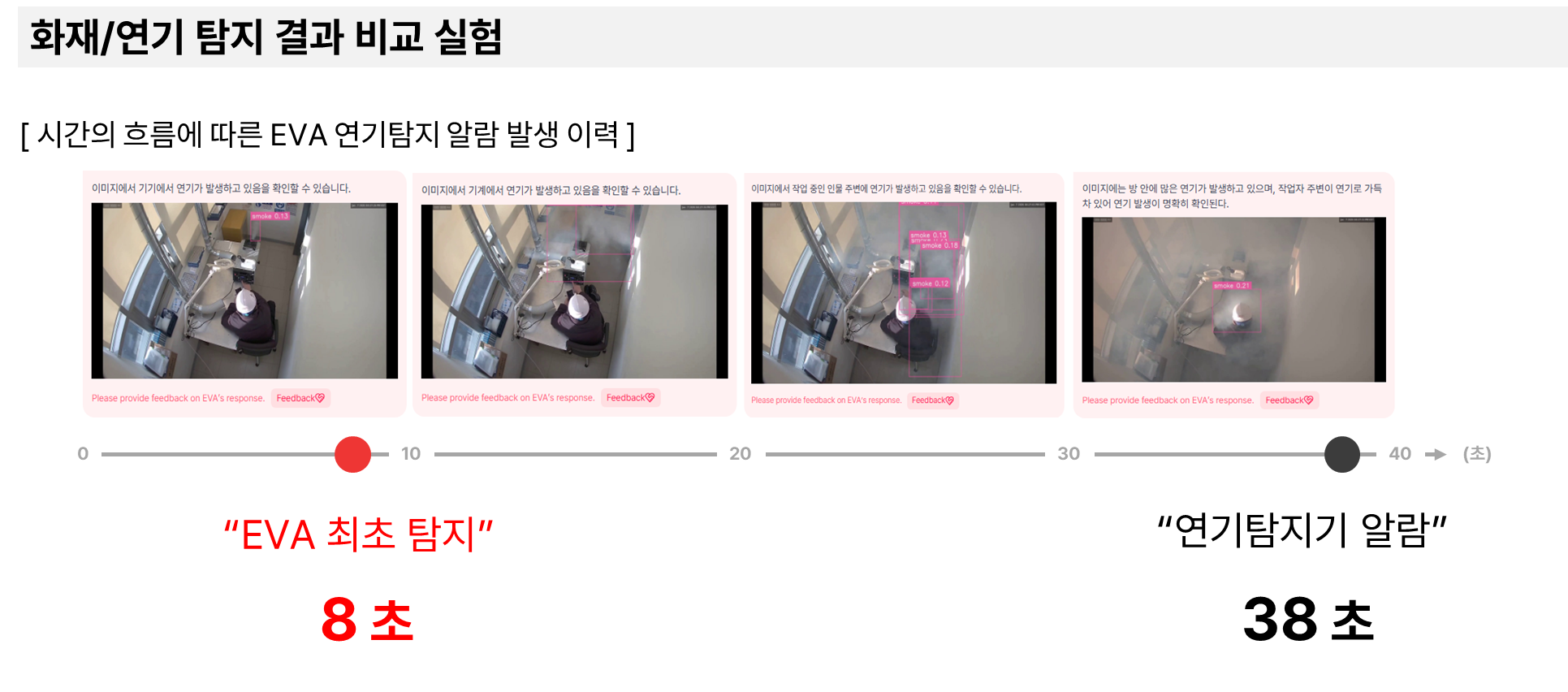

Field Validation Test: 8 Seconds vs. 38 Seconds

A smoke detection test simulating a real fire scenario was conducted at an LG Electronics production site. The core objective of this test was to compare the detection speed between the existing smoke detectors and the newly introduced EVA system.

The results were highly encouraging. Based on the moment when smoke began to rise, the average response times of each system were as follows:

EVA: Smoke detected approximately 8 seconds after occurrenceConventional smoke detector: Smoke detected approximately 38 seconds after occurrence

As a result, EVA identified and propagated the hazardous situation more than four times faster than conventional smoke detectors. This 30-second difference represents a decisive window that can determine the success or failure of initial fire suppression.

Physical Contact vs. Immediate Visual Detection Mechanisms

This performance gap originates from a fundamental difference in detection mechanisms.

Traditional smoke detectors only respond when smoke physically enters the sensor chamber. In other words, smoke must rise to the ceiling and reach the detector before an alarm is triggered. In environments with high ceilings or active ventilation systems, smoke diffusion is often delayed, inevitably slowing down detection.

EVA, on the other hand, captures visual changes instantly. Even before smoke reaches the ceiling, EVA analyzes subtle movements and color variations of early-stage smoke in real time to assess potential risk. During this test, EVA responded immediately at the very early stage of smoke generation and issued alerts without waiting for physical diffusion, clearly demonstrating superior detection efficiency.

Beyond Single-Purpose Sensors: Toward a Scalable Intelligent Safety Platform

The results of this test demonstrate that EVA goes beyond a simple fire detection solution, presenting a new paradigm for on-site safety management. While traditional physical sensors are designed to perform a single, isolated function, EVA combines cameras with AI-based analytics to recognize multiple situations simultaneously.

In addition to fire detection, EVA can identify a wide range of risk factors in real time, including worker falls, missing safety equipment, abnormal equipment vibrations, and fluid leaks. In this sense, EVA serves as a “digital eye” for industrial sites, expanding the scope of safety management while dramatically improving response speed.

The Future of AI-Driven Integrated SHEE Monitoring

The adoption of EVA represents more than a simple technology upgrade—it marks the evolution toward an integrated SHEE monitoring system. With AI-powered real-time analysis and automated alerting, organizations can proactively prevent incidents and respond immediately when risks arise.

Moving forward, EVA’s AI capabilities will continue to advance, enabling the construction of a Physical AI–based integrated safety platform that ensures accident-free and safe working environments across all operational sites.