Bolt Fastening Solution Service

Experience bolt fastening inspection from factory data through an AI Solution created based on Tabular Anomaly Detection AI Contents.

Service Environment Setup

One of the common tasks in a factory is bolt fastening. In this task, bolts are fastened to parts using a target torque set on an Electronic Torque Controller, an electric tool, to ensure that they are tightened to the target torque.

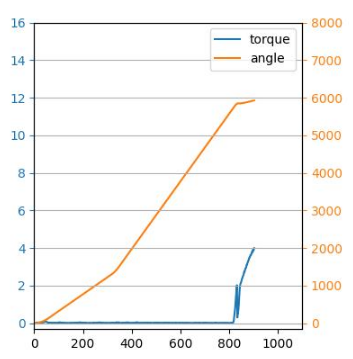

The data generated in this process initially shows no torque applied to the tool, then the torque increases as the bolt is tightened. The Electronic Torque Controller can sense this data and store it in structured or unstructured forms, which can be utilized to provide AI inspection services.

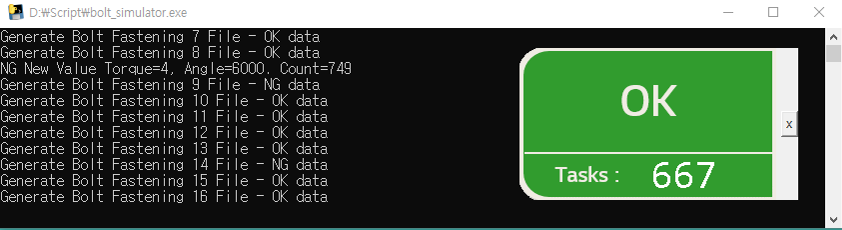

To utilize bolt fastening data, a Bolt Fastening Data Simulator is provided. This simulator generates bolt fastening data every 5 seconds in the set path and includes NG data according to the ng_ratio.

This allows you to operate AI Solution services using data similar to what occurs in the factory.

Download Link: Bolt Fastening Data Simulator

The simulator generates csv files based on the path set in config.ini with target_torque and count parameters as follows:

| Time | Count | TargetTorque | Torque | Angle |

|---|---|---|---|---|

| 10:52:35 | 1012 | 2 | [0.01, ... 0.96,14.26,15.00] | [0, 4, ... 186,195,204] |

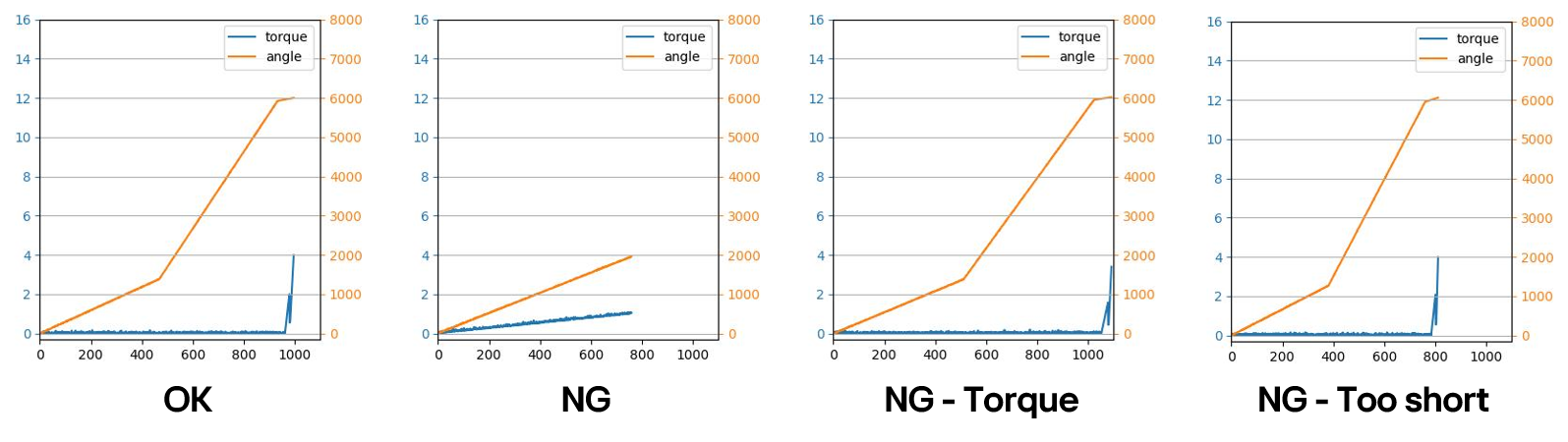

NG data is generated according to the ng_ratio, and a graph comparing the patterns of OK and NG data looks as follows. The torque value must reach the Target Torque at the end. Although different types of bolts may produce patterns similar to OK data but with different overall lengths, failed fastening can result in entirely different graphs.

Windows PC

For operating the Bolt Solution on the PC where the Edge App will be installed, the following specifications are recommended:

- CPU: i5

- Memory: 8GB

- OS: Windows 10

Align the DataInputPath of the Edge App with the path set in config.ini of the simulator.

AI Solution Operation

Deploying Inference Model for Data Collection

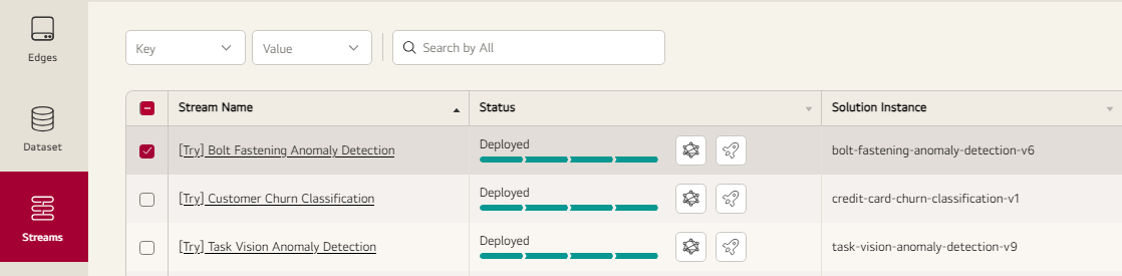

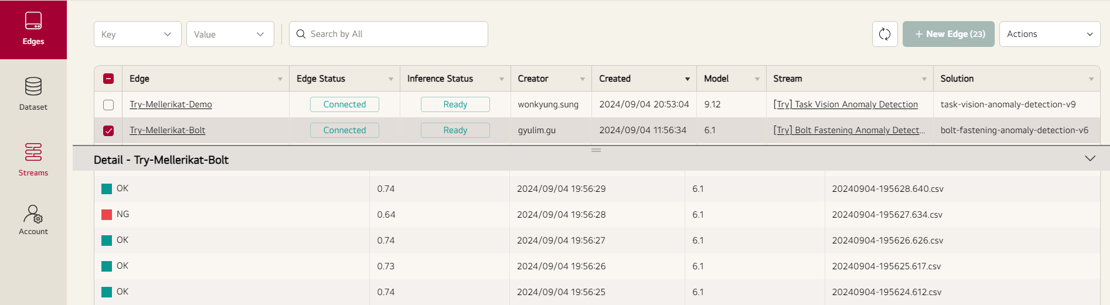

Deploy the Bolt Fastening Anomaly Detection v1.1 model to the Edge App through the Stream page of Edge Conductor to perform inference.

Once deployment is complete, the Edge App will switch to Disconnected status and then to Connected status after downloading and executing the inference Docker.

The Bolt Fastening Anomaly Detection Solution reads csv files, extracts features for modeling, and makes judgments. It generates graphs for labeling in Edge Conductor, which can also be viewed through the Edge Viewer on Windows PC.

Data Collection

Run the Edge App, then run Tiny Viewer and the simulator to collect about 100 data entries.

If the Edge App operates correctly, it will perform inference and display it on Tiny Viewer.

Note: If the Edge App does not operate, double-check the DataInputPath set during installation.

Since the v1.1 model is trained with a small amount of data, it may make uncertain inferences, resulting in low scores and incorrect judgments.

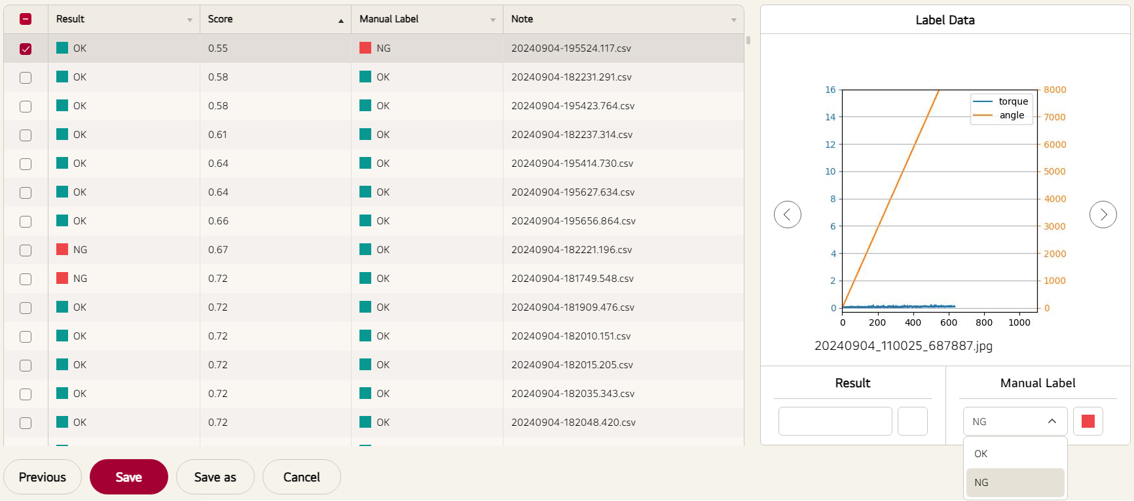

Dataset Creation and Labeling

Move to the Dataset menu to create and label a Dataset based on the data inferred by the Edge App. Sorting based on the score can help save time by labeling the uncertainly judged data first.

Refer to Dataset Manual for more details.

Model Training and Deployment

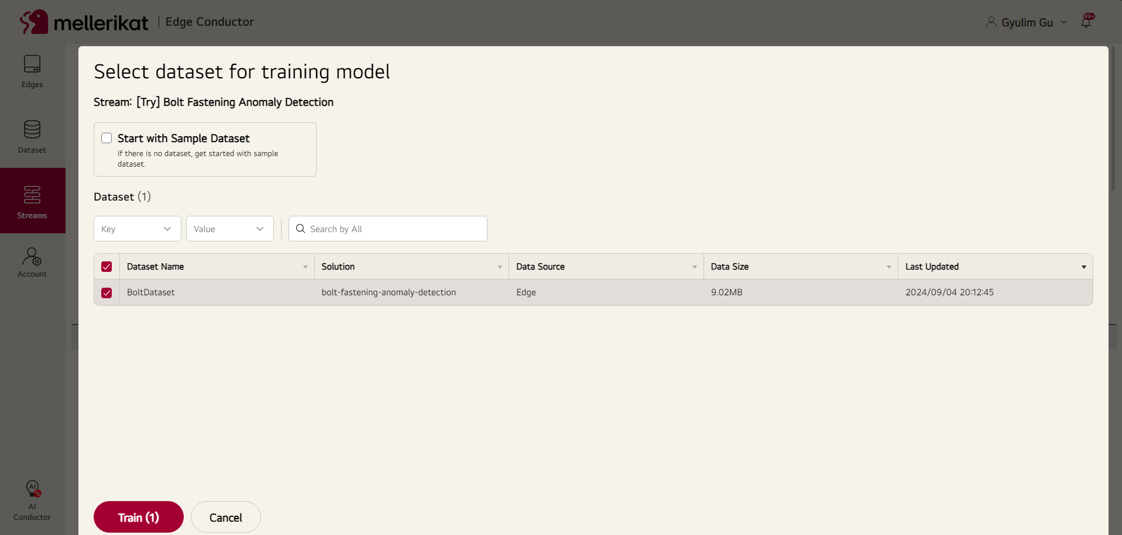

Click the Train button for Bolt Fastening Anomaly Detection in the Streams menu, select the created Dataset, and request training.

Once requested, the Dataset's data is sent to the cloud S3, and AI Conductor retrieves and runs the training pipeline to generate a model.

After the training is complete and a model higher than v1.1 is created, AI Conductor sends the model to Edge Conductor, making it ready for deployment to the Edge App.

Click the deployment button again to deploy the model to the Edge App and verify its judgment quality.

Refer to Model Train Manual for more details.

Inference

Run bolt_simulator.exe again to periodically generate data and check if the model makes predictions. The prediction results can be viewed on the Edge Viewer on the left or the Tiny Viewer on the right.

Tiny Viewer is used to run the AI solution without obstructing the task instruction screen or the screens of the existing systems in the factory. Additionally, due to its optimized structure, the Edge App provides the AI model's prediction results immediately upon data generation, allowing operations to continue without affecting task time.

Retraining

A model trained with a small amount of data may have limited performance. In such cases, collect additional data, label the incorrect judgments, and improve the AI model through retraining.

Since you can easily collect additional data, create Datasets in Edge Conductor, and perform training and deployment of AI models, AI Operators in the field can manage and operate the AI models.

For more details on the role of AI Operator, refer to AI Operator Manual.

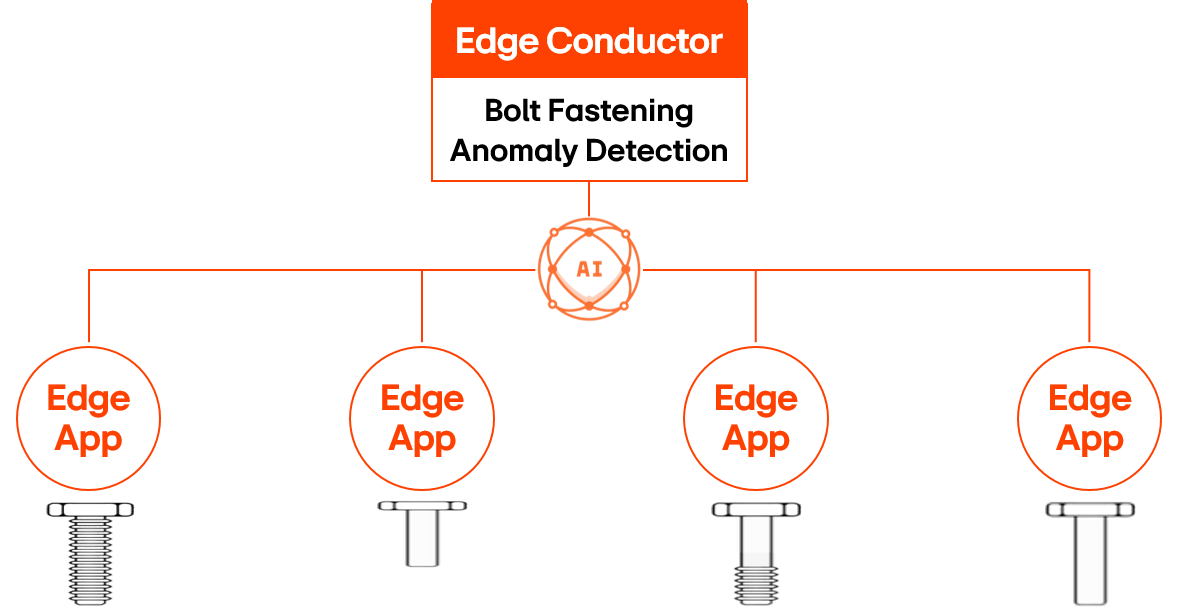

Scalability

Having developed the AI Solution and established the modeling structure, it can be applied and operated on various Edge Apps.

Each Edge App may involve different types of bolts with different types of normal data. However, by using Edge Conductor, you can create Datasets with this data, train models, and deploy them.

This allows for the efficient operation of AI solutions through the Mellerikat platform, even with multiple bolt fastening processes in the factory.